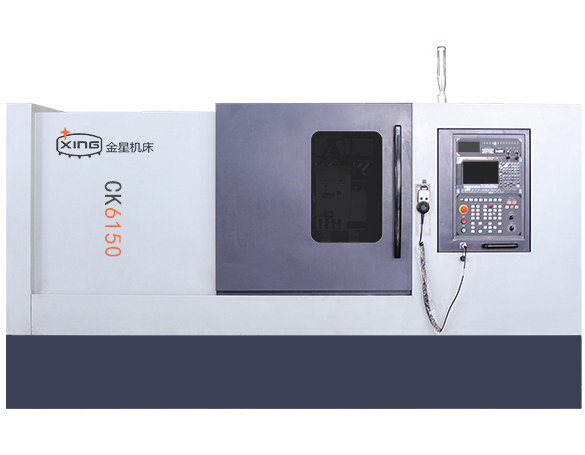

CNC lathe, also known as CNC lathe, is the largest domestic use, the most extensive coverage of a CNC machine tool. CNC lathe is a set of mechanical, electrical, hydraulic, pneumatic, microelectronics and information technology as one of the electromechanical integration products. As a machine tool manufacturing history of more than 50 years of CNC lathe manufacturers, our CNC lathe products have hard rail CNC lathe, line rail CNC lathe, oblique bed CNC lathe, high precision CNC lathe, etc., welcome to inquire CNC lathe price.