Temporarily no data

CK6130h high precision

High precision CNC lathe, large span headstock design, integral structure frame, with high rigidity, high shock resistance and other characteristics.

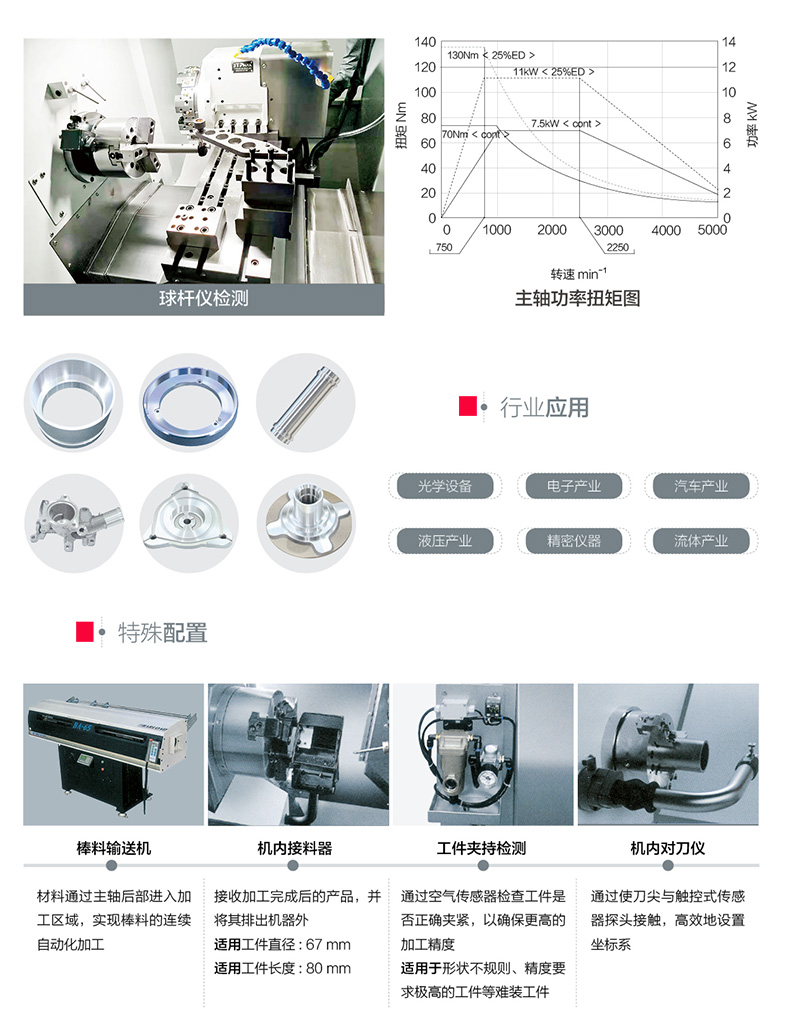

The standard configuration

FANUC SIEMENS

Optional configuration

Feeding machine, in-machine feeder, workpiece clamping detection, in-machine tool, etc

The product description

CAK6130hi CNC lathe is a high-speed, high-precision CNC lathe, with turning cylindrical surface, conical surface, circular surface, inner hole, grooving and a variety of threads and other processing functions, suitable for a variety of parts of single, small batch or batch production.

All castings are made of resin sand material with high dimensional accuracy, strong rigidity and good surface quality. The castings are processed by artificial aging and vibration aging to reduce and homogenize the residual stress of each workpiece, prevent the deformation of the workpiece, improve the wear resistance, stability and vibration resistance of the machine tool, and make the machine tool continuously and stably process at high speed for a long time.

。

Product advantage

First, the bed adopts the integral box casting structure, the overall rigidity of the bed is good, easy for the operator to load and unload materials and automatic chip removal. The inner part of the casting is covered with reinforcing bars to resist bending and shock absorption, and verified by finite element analysis, so as to ensure the long-term stability of the cutting performance and accuracy of the machine tool.

Second, the headstock adopts a large span, closed box structure, with high rigidity, high shock resistance and other characteristics; Spindle nose end model A2-5, bearings using imported high-precision radial angular contact ball bearings, can withstand sufficient radial and axial forces. The whole sleeve spindle maintains proper pre-pressure, and can maintain high speed for a long time, and the heat and vibration values are low.

3, X, Z axis adopts imported linear guide rail and ball screw, running speed, high precision, long service life; Lead screw bearing for independent installation, separate assembly and adjustment, using a row of tool holder, tool change speed, high accuracy, low failure rate. Mechatronics design, easy operation and maintenance; Independent large water tank and iron filings box, iron filings can be quickly discharged.

Technical parameters

| ITEM | 单位 | 主要规格参数 |

| max. diameter over the bed | mm | 500 |

| max. diameter over the table | mm | 180 |

| z axis stroke | mm | 330 |

| x axis stroke | mm | 300 |

| X fast speed | m/min | 30 |

| Zf ast speed | m/min | 30 |

| spindle speed | r/min | 100-5000 |

| spindle type | A2-5 | |

| spindle MT | MT | 6 |

| spindle hole | mm | 55 |

| hydraulic chuck | in | 6(英寸) |

| chuck diameter | mm | 45 |

| main motor | Kw | 7.5 |

| L*W*H | mm | 1900*1700*1800 |

| GW/NW | Kg | 2800/2500 |

Typical artifacts