Product introduction

The product description

Product advantage

Technical parameters

Typical artifacts

The special custom

Temporarily no data

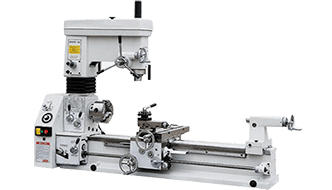

XH7126小型立式加工中心

三轴直线导轨、进口主轴总成、伺服主电机、占地小效率高

The standard configuration

凯恩帝数控系统、伺服主轴、圆盘式刀库

Optional configuration

其他品牌数控系统、排屑机、自动上料机械手

The product description

XH7126小型加工中心是金星机床专门为小型工件高速高效加工而研制的一款小立加,可以完成钻削、铣削、镗孔、扩孔、铰孔的自动工作循环,定位和重复定位精度高,可靠性好,能够实现对盘类、板类、壳体、模具等复杂、高精度零件的加工,适于多品种各中、小型零件的平面、斜面、沟槽、孔等多种工序加工,是机械、电子、仪器、仪表、模具、汽车等行业的理想加工设备。

Product advantage

XH7126小型立式加工中心在设计中注重刚性、精度及精度保持性、易操作性和维修性这三个用户最为关心的问题,其突出特点是:

1、采用床身式结构、采用高强度铸铁材料、合理布筋,具有极好的刚性。立柱采用“人”字型结构,刚性、稳定性可靠。

2、X、Y、Z轴采用滚珠丝杠,运动精度高;X、Y、Z轴采用直线导轨,运行速度快加工效率高。

3、主轴单元采用伺服电机经同步带驱动精密高速主轴(BT40锥孔)的结构。

4、具有完备的自动润滑、切削液循环等系统。

5、采用高性能数控系统及进给伺服驱动、伺服电机。

6、结构优化设计,在不牺牲刚性、稳定性和三轴行程的前提下缩小机身,减小占地面积节约厂房空间。

Technical parameters

| 项 目 | 内 容 | 单 位 | 参 数 |

|

加 工 范 围 | 工作台纵向(X轴)移动最大距离 | mm | 400 |

| 工作台横向(Y轴)移动最大距离 | mm | 350 | |

| 主轴箱立向(Z轴)移动最大距离 | mm | 430 | |

| 主 轴 | 主轴转速范围 | r/min | 50~8000(无级) |

| 主电机功率 | kw | 3.7 | |

| 主轴锥孔 | BT40 | ||

| 主轴中心到立柱导轨面距离 | mm | 340 | |

| 主轴鼻端到工作台表面距离 | mm | 50-480 | |

| X、Y、Z方向为线轨 | |||

| 工作台 | 工作台尺寸 | mm | 300x600 |

| X、Y、Z向进给速度范围 | m/min | 20/20/20 | |

| 精度 | X、Y、Z定位精度 | mm | 0.016 |

| X、Y、Z重复定位精度 | mm | 0.006 | |

| 其它 | 冷却泵电机功率 | kW | 0.125 |

| 三轴伺服电机扭距 | N.m | 6 | |

| 罩壳 | 全封闭罩壳 | ||

| 机床外形尺寸(长×宽×高) | mm | 1800x1500x2550 | |

| 机床净重 | kg | 2200 |

Typical artifacts

The special custom

Shandong

Linyi Jinxing Machine Tool Co.,

LTDThe former Linyi Machine Tool Factory, founded in 1965, is a state-level high-tech enterprise mainly engaged in research and development, production and manufacture of electromechanical CNC machine tools and characteristic export products, with annual productionVertical machining center、CNC milling machine、Numerical control lathe、Ordinary lathe、Turn milling compound machine、Surface grinding machineThe company has passed IS09001 international quality system certification, and enjoys the right of import and export. It is a patent star enterprise in Shandong Province and has a provincial enterprise technology center.

I plant many years of special machine custom experience, in generalNc machine tool、Processing center, on the basis of process integration, and equipped with rotary table, dynamic milling head, combination milling first, design the crankshaft machining for machine tool, special processing machine tool, connecting rod water watchcase processing machine tools, aviation plug machine, gasoline engine shell chamfering machine, hydraulic pipe production machine, etc. The production efficiency is generally improved by more than two times, and the labor cost is reduced by several times.

Welcome to inquire, pre-sale engineer will be at your service wholeheartedly.

The machine tool